Tobacco

The growth and production of tobacco brought wealth, jobs and growth to Motueka and was integral to the social fabric of the district for more than 70 years. But the financial well-being of the crop and the growers was often at the mercy of the Government

The growth and production of tobacco brought wealth, jobs and growth to Motueka and was integral to the social fabric of the district for more than 70 years. But the financial well-being of the crop and the growers was often at the mercy of the Government..

For more than seven decades, the Motueka district’s tobacco fields provided work for locals and itinerant workers: topping plants, nipping out laterals and picking leaves.1

Tobacco seeds and the smoking habit were brought to New Zealand by sealers and whalers in the first half of the 19th century. Māori began growing tobacco in Rotorua in 1839.2

As early as 1843, Mr McGee’s tobacco leaf earned special mention in the first Nelson Agricultural Show, and Pastor Heine planted 50 plants in the Upper Moutere in 1850.3 By the end of the 19th century, tobacco was beginning to appear in the Riwaka district, where Māori growers were known for producing excellent crops.4

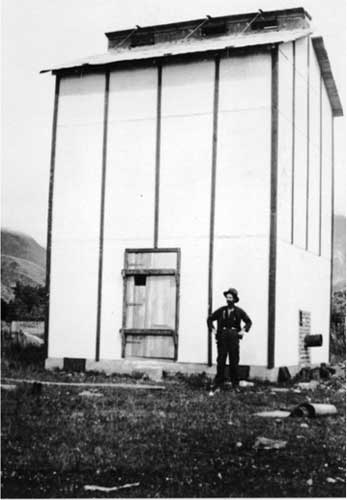

There were several key players in the development of Motueka’s tobacco industry. In 1918, Charles Lowe grew tobacco on his Harakeke farm and built New Zealand’s first flue-curing barn.5

Meanwhile, in the early 1920s, Brightwater farmer, Cecil Nash, working for the National Tobacco Company, persuaded farmers in the area to plant tobacco. In 1925-26, more than 150 acres of tobacco were under contract to the Company. By the 1926-27 season, two companies were buying the district’s tobacco: the National Tobacco Company and W.D. and W.O. Wills.6

A growers’ association was established at Riwaka in 1926 and by the early 1930s, 90% of New Zealand’s commercial tobacco was grown in the Nelson region. In 1933, tobacco was the most widely grown crop in the district and there were about 700 growers.7

In July 1934, about 100 growers went to Parliament to meet the Customs Minister, Joseph Gordon Coates, to argue that duty concessions would easily be offset by the income generated by the tobacco growing industry. Coates told the growers that the Government had to raise £1,600,000 in revenue from tobacco.8

A Tobacco Industry Act was passed in 1935 to try to co-ordinate the industry and solve issues such as over-production. A Tobacco Board was established, with all growers licensed to ensure they had a guaranteed buyer and planted no more than they could process.9

Legislation did not solve all the ills of the industry and by 1938 grower numbers had fallen to 342, even though tobacco could supply a good, steady income. The Board aimed to stabilise the industry, and increase acreage and the number of growers. A research station was established near Riwaka in 1938 and began to research mosaic disease - a crippling disease which causes mottled colouring and blistering on leaves.10

Wartime demand and Government assistance saw significant increases in acreages from 2000 acres in 1936, to nearly 3000 acres in 1941.11

The industry continued to provide a good living for many families in the district, with the number of growers peaking at 763 between 1960 and 1964. In 1989, WD and HO Wills closed its packing plant after 61 years in the district.12

Rothmans withdrew in 1995, citing low international leaf prices and declining tobacco use. The demise of the now-deregulated tobacco industry was a $5-$6 million/annum blow, with many growers diversifying into other crops. Nowadays, apple trees are the most common sight in the Motueka district.13

From Tobacco Leaf to Cigarettes

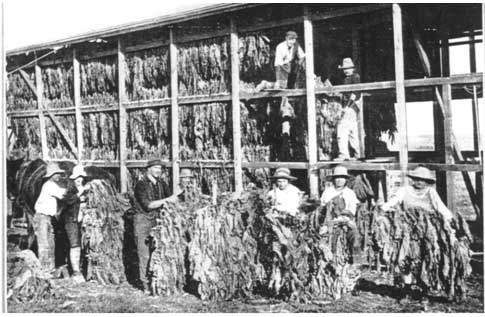

Corrugated iron drying kilns were a familiar sight throughout the district and three packing plants in Motueka were major employers. Air dried tobacco (known as burley) was the mainstay of the tobacco industry until the late 1920s. It required no specialized equipment: the leaves were dried, then stripped from the plants, sorted, hanked into bunches of 15 or 20 leaves and pressed - usually in a hop press.

Flue-cured or kiln dried tobacco involved tobacco leaves being tied on sticks, with up to 750 sticks being loaded into drying kilns. The kilns (wood-fired initially and later by coke and coal) had to be watched around the clock and the temperature raised in stages to 170-180 ºC. After curing, the leaves were lightly steamed for ease of handling, then graded and packed in large bales, where they were shipped to processing factories such as the Wills’ cigarette factory in Petone, Wellington.14

2008

Read more about tobacco in the Nelson region. An essay by Kaitlyn Turner, written as an NCEA assignment, 2016. [PDF]

Updated December 6, 2021

Story by: Joy Stephens

Sources

- MacKay, D. (1998, February 21) The days of golden harvest. Nelson Evening Mail p.13.

- O'Shea, P. K. (1997). The Golden Harvest : A History of Tobacco Growing in New Zealand, Christchurch, N.Z.: Hazard Press, p. 12.

- O'Shea, P. K. p. 17.

- McAloon, J. (1997) Nelson: a regional history. Whatamango Bay, N.Z.: Cape Catley in association with Nelson City Council, p. 100.

- O’Shea, P.K. p. 18.

- O’Shea, P.K. p. 23, 25.

- McAloon, J. p 160-161.

- O’Shea, P.K. p. 69.

- McAloon, J. p. 160-161.

- O’Shea, P.K. p. 78-80.

- McAloon, J. p. 192.

- MacKay, D.; Clark, Karen (2001, 12 February). New Crops suggested for region, The Nelson Mail, p.3.

- Tocker, Alison. (1995, 11 October) Motueka `loses $15m'. The Dominion Post, p.18.; Crean, M. (2006, April 29) Growing pains near Riwaka. The Press p.D4.

- O’Shea, P.K. p. 29-35.

Further Sources

Books

- Bastin, S. H. (2018). Nicotine Flavoured Scones For Smoko. Christchurch, N.Z.: Shirley Heath Bastin.

https://www.worldcat.org/oclc/1059562496 - Curtis, K. M. (1941). Tobacco mosaic incidence in Nelson district : advice to growers about control. Nelson, N.Z.: Cawthron Institute.

https://www.worldcat.org/oclc/156792642 - DSIR tobacco research station Motueka. (1978). In New Zealand. Science Information Division. (Ed.), Science Information Division, DSIR.

https://www.worldcat.org/oclc/153377004 - Henderson, J. (1954). A tobacco farm. Wellington, N.Z.: School Publications Branch, Dept. of Education.

https://www.worldcat.org/oclc/55719047 - Henderson, J. (1986). Jim Henderson's people. Auckland, N.Z.: Reed Methuen.

https://www.worldcat.org/oclc/154529066 - Horrocks, S. (1971). Historic Nelson. Wellington, N.Z.: A.H & A.W. Reed Ltd.

https://www.worldcat.org/oclc/45791554 - McAloon, J. (1997). Nelson: a regional history. Whatamango Bay, N.Z.: Cape Catley in association with Nelson City Council.

https://www.worldcat.org/oclc/50310188 - Motueka District Progress League.(1935).Motueka and district. Motueka, N.Z.: Motueka District Progress League, p.23.

https://www.worldcat.org/oclc/153661181 - Munro, I. (1999). Back then. Threads from Motueka's past. Motueka, N.Z.: Motueka High School with the assistance of the Tasman District Council, p. 32.

https://www.worldcat.org/oclc/154311096 - New Zealand Tobacco Growers' Federation & Dual Associates. 1980 Motueka District tobacco industry proposals to government. .Motueka, N.Z.: N.Z. Tobacco Growers Federation.

https://www.worldcat.org/oclc/155721414 - O'Shea, P. K. (1997). The Golden Harvest : A History of Tobacco Growing in New Zealand, Christchurch, N.Z.: Hazard Press.

https://www.worldcat.org/oclc/44587921 - Rigg, T. & Chittenden E. T. (1951).Classification of land in the Waimea County, Nelson, for flue-cured tobacco. Nelson, N.Z.: Cawthron Institute?.

https://www.worldcat.org/oclc/156215412 - Tobacco Institute of New Zealand. Arthur Young & Company. (1988). The economic impact of the New Zealand tobacco industry. Auckland, N.Z.: Tobacco Institute of New Zealand.

https://www.worldcat.org/oclc/153312656 - Tobacco Research Station. (1975). Tobacco production and research in New Zealand Tobacco Research Station. Riwaka, N.Z.: Tobacco Research Station.

https://www.worldcat.org/oclc/152398449 - Walker, H. H. (1996). A (re)definition of rural space and the changing identities of women on tobacco farms in Motueka. Dunedin, N.Z.: University of Otago?

https://www.worldcat.org/oclc/152403105

Tobacco industry generally

- James, R. W. (1970). In Tobacco Research Station. (Ed.), Tobacco production in New Zealand / R.W. James Dept. of Scientific and Industrial Research, Tobacco Research Station.

https://www.worldcat.org/oclc/153377057 - New Zealand Tobacco Company. (1928). Prospectus of the New Zealand Tobacco Company Limited. Auckland, N.Z.: R.J.K. Simpson.

https://www.worldcat.org/oclc/191752923 - New Zealand. Committee of Inquiry into the Economic Position of the Tobacco Growing Industry in New Zealand. (1971). The economic position of the tobacco growing industry in New Zealand. Wellington, N.Z.: Govt. Print.

https://www.worldcat.org/oclc/153708927 - Sutherland, G. F. (1901). Tobacco-growing in New Zealand. Wellington, N.Z.: New Zealand Dept. of Agriculture.

https://www.worldcat.org/oclc/181914797 - Thomson, R. (1948). Flue-cured tobacco growing in New Zealand. DSIR .Wellington Dept. of Scientific and Industrial.

http://www.worldcat.org/oclc/973437549 - Walsh, A. (1884).Tobacco culture in New Zealand. Auckland, N.Z.: Auckland Tobacco Company.

https://www.worldcat.org/oclc/152394289 - Wise, H. L. (1945). Tobacco growing and manufacture in New Zealand. Christchurch, N.Z.: Whitcombe & Tombs.

https://www.worldcat.org/oclc/39101421

Newspapers

If you are interested in reading the following articles please contact your local library.

- Booker, M. (1989, July 25), Tobacco company pull out accepted bravely in Motueka. Dominion, p.6.

- Clark, Karen (2001, February 12). New Crops suggested for region, The Nelson Mail, p.3.

- Cottier, W Gourlay, E S. (1955, 15 October). New horticultural pest found on Nelson tobacco. New Zealand Journal of Agriculture 91, p.349-351.

- Crean, M. (2006, April 29). Growing pains near Riwaka. The Press , p.D4.

- Davis, K. (1989, August 16). Tobacco industry in crisis. New Zealand Farmer 111,.32, p.6-7.

- Dick, A. (2007, August/September). Motueka. NZ Today 23, p.68-75, 78-90.

- Dissmeyer, T. (1995, February 5), Town braces for tobacco withdrawal. Sunday Star Times, p.A7.

- The end of the golden leaf. (1995, July 10). The Guardian p.10-20.

- Gillespie, O.N. (1939). New Zealand Industries Series: Tobacco. The New Zealand Railways Magazine 14, p.2.

http://www.nzetc.org/tm/scholarly/tei-Gov14_02Rail-t1-body-d4.html - Hyde, W. C. (1946). History of tobacco growing in NZ. New Zealand Journal of Agriculture 72, 5, p.457-459.

- MacKay, D. (1998, February 21) The days of golden harvest. Nelson Evening Mail p.13.

- Mackay, D. (1996, July 25). Tobacco industry won't roll over and die. Nelson Mail

- Moore, C. (1998, Mar 2). Tobacco's wistful roads; roll your own 'boutique' supplies. The Press, p.23.

- O'Connor, N. (1995, May). End of the golden crop: the last tobacco harvest. North and South.p.94-100.

- Tobacco seized in Motueka. (2010, May 5). Nelson Mail.

http://www.stuff.co.nz/nelson-mail/news/3660067/Tobacco-seized-in-Motueka - Tocker, Alison. (1995, 11 October) Motueka `loses $15m'. The Dominion Post, p.18

Websites

- 'Soil and Climate'. From An Encyclopaedia of New Zealand, edited by A. H. McLintock, originally published in 1966. Te Ara - The Encyclopedia of New Zealand:

http://www.teara.govt.nz/en/1966/farming-arable-tobacco/1 - McAloon,J. 'Hops, tobacco and hemp - Tobacco', Te Ara - the Encyclopedia of New Zealand, p.2.

http://www.TeAra.govt.nz/en/hops-tobacco-and-hemp/page-2 - People of Motueka (1963, June). Te Ao Hou, 43, p.38-40.

http://teaohou.natlib.govt.nz/journals/teaohou/issue/Mao43TeA/c16.html

Maps

DVD

- New Zealand Tobacco Industry Historic Trust. (1998). The end of the golden weed: The story of tobacco growing in the Motueka area : personal memories of a unique industry, 1920's - 1990's.[DVD]. Motueka, N.Z.: New Zealand Tobacco Industry Historic Trust. (Held at Tasman District Libraries).

http://www.worldcat.org/oclc/813343405

Watch online

- Hughan, O., & Fowler, H. (1964). 'Motueka', These New Zealanders. [TV programme] N.Z.: National Film Archive. Retrieved 7 December 2021 from NZ On Screen:

https://www.nzonscreen.com/title/these-new-zealanders-motueka-1964 - Lloyd, V. S. (1938). NZ Review No.8: Sunshine Provence. NZ National Pictures. [Moving picture]. F3418. Retrieved 7 December 2021 from Ngā Taonga Sound & Vision:

https://ngataonga.org.nz/collections/catalogue/catalogue-item?record_id=64742 - Neill, S. (1978). New country: new people. National Film Unit. [Documentary]. Retrieved 7 December 2021 from NZ on Screen:

https://www.nzonscreen.com/title/new-country-new-people-1978/overview

Image links

- There are a number of New Zealand archives, libraries and museums that hold photographs or video of Motueka tobacco. Many of these images can be accessed through the Digital NZ website